Production

90 to 500 ton Injection Molding for Short and Long Run Jobs

Reliable Injection Molding With Consistent,

Repeatable Performance

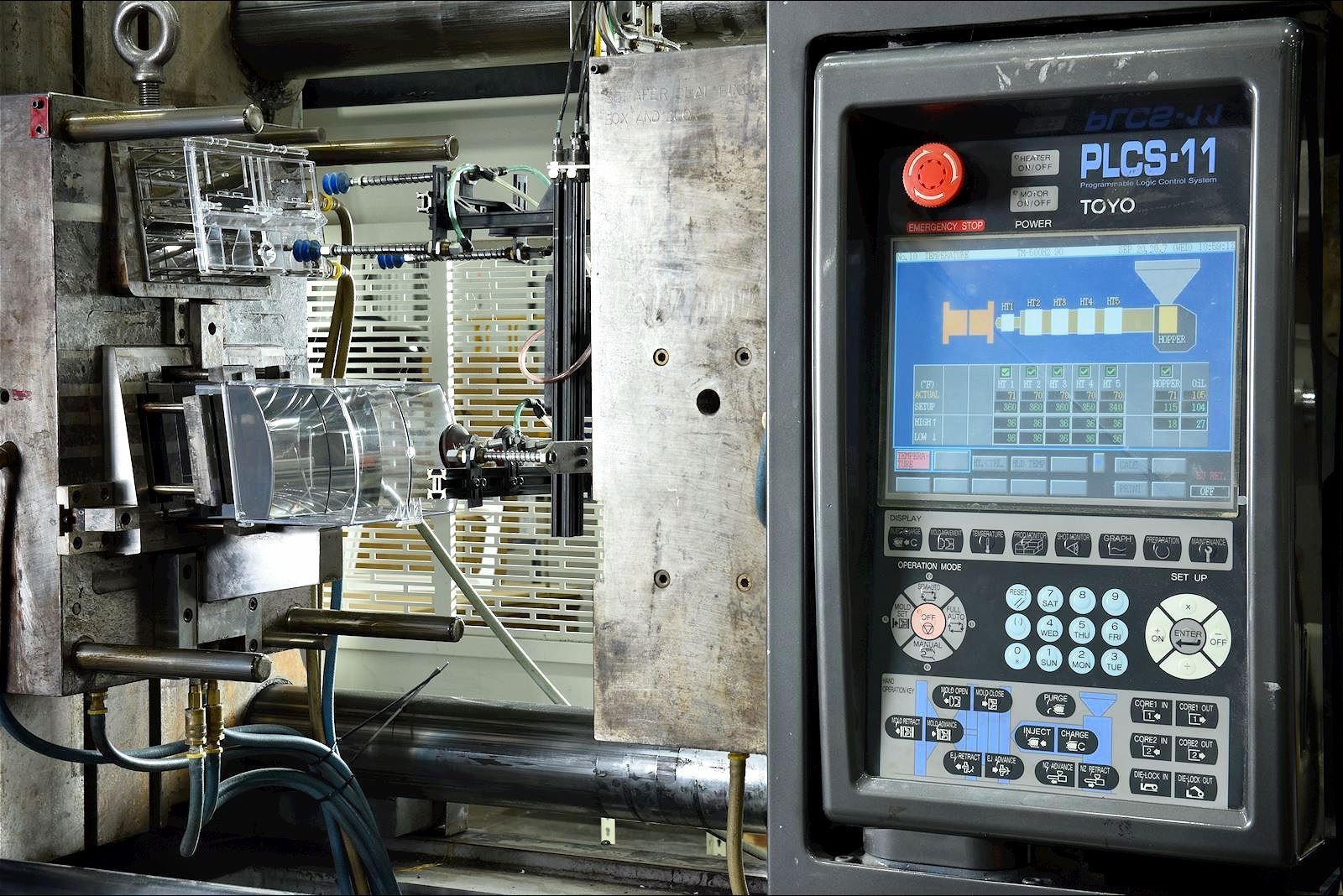

R&D Engineering operates a modern injection molding facility built around stability, efficiency, and predictable output. Our production floor runs 23 TOYO presses ranging from 90 to 500 tons, giving us the flexibility to support a wide range of part sizes, materials, and application requirements.

Every job is set up with a focus on process control and repeatability, ensuring your parts meet the specifications you expect.

Modern Equipment for Stable, Efficient Production

Our press lineup is fully computer‑controlled, allowing for precise shot control, consistent cycle times, and clean operation. This equipment supports both short‑run projects and long‑term production programs with equal reliability.

Key advantages include:

- Tight process control

- Predictable cycle‑to‑cycle performance

- Efficient material usage

- Reduced variability across runs

This foundation helps maintain part quality while supporting efficient throughput.

Process Monitoring and Quality Focus

Each production job is monitored closely to maintain consistency and identify any deviations early. Our team follows established procedures for setup, verification, and in‑process checks to ensure your parts meet dimensional and visual requirements.

This disciplined approach supports:

- Dimensional accuracy

- Material consistency

- Stable molding conditions

- Reliable long‑term performance

- Flexible Support for a Range of Applications

We produce components for industries with varying performance expectations, including:

- Medical

- Industrial

- Agricultural

- Construction

- Consumer products

Regardless of the application, our focus remains the same: stable production, dependable quality, and clear communication throughout the process.

Efficient Transition From Tooling to Production

Because tooling, engineering, and production operate under one roof, we maintain tight coordination during launch and throughout the life of your program. This integration helps reduce downtime, streamline adjustments, and keep your project moving without unnecessary delays.

If you have a design, an idea, or a prototype for a plastic injection molding production process, contact R & D Engineering and we will help you achieve production success.