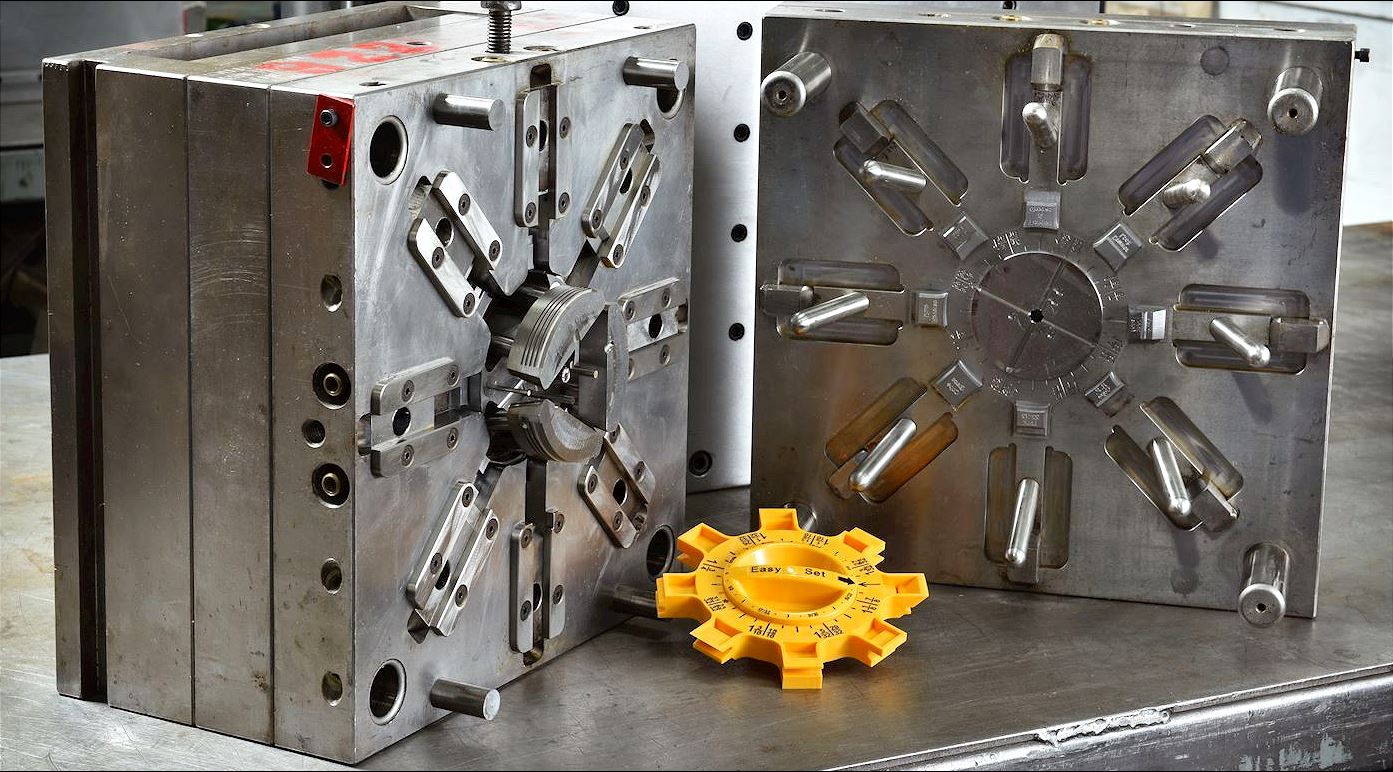

Mold Making

Tooling Engineered for Accuracy, Reliability, and

Long‑Term Performance

A well‑built mold is the foundation of consistent injection‑molded parts. At R&D Engineering, we design and build tooling with a focus on precision, durability, and efficient production. Our team combines decades of experience with modern machining technology to create molds that support stable, repeatable manufacturing.

Practical, Engineering‑Driven Collaboration

Every project starts with understanding the functional requirements of your part. From there, we design tooling that supports manufacturability, cycle efficiency, and long‑term performance. Our approach is straightforward and grounded in real production experience.

You can expect:

- Clear communication throughout design and build

- Practical recommendations based on proven tooling methods

- A focus on producing a mold that runs cleanly and consistently

In‑House Tool Room for Speed and Control

Keeping tooling in‑house allows us to maintain tighter control over quality and timelines. It also enables faster adjustments, efficient maintenance, and a smoother transition into production.

Our capabilities include:

- New mold design and build

- Multi‑cavity and family molds

- Complex geometries and precision components

- Tooling repairs and maintenance

- Engineering changes and revisions

This integrated setup helps reduce downtime and keeps your project moving.

Built for Consistency and Efficient Production

We engineer molds to support predictable, repeatable performance. Attention to detail in design and construction helps ensure:

- Balanced material flow

- Effective cooling

- Robust construction

- Maintainability

- Stable cycle times

The result is tooling that supports reliable production, whether for short runs or long‑term programs.